Supply chain hiccups can quickly cascade into financial tremors that shake the core of your enterprise. In other words, if your supply chain goes belly up, it can spell disaster for the entire company.

As a Chief Financial Officer (CFO), you’re tasked not just with navigating these choppy supply chain waters, but also with fortifying the business against any potential storm.

So, how can you mitigate supply chain risks as effectively as possible?

Find out in this article, where we explore five key supply chain risk mitigation strategies to help you steer your company toward financial stability and resilience. Learn how to:

- Spot pesty risks in your supply chain before they become a problem

- Cast a wider safety net by diversifying your supply chain

- Gain more visibility by leveraging robust supply chain technologies

- Create contracts and compliance procedures

- Build a resilient supply chain

But before we get into the supply chain risk mitigation strategies, let’s touch base on what types of risks to look out for.👇

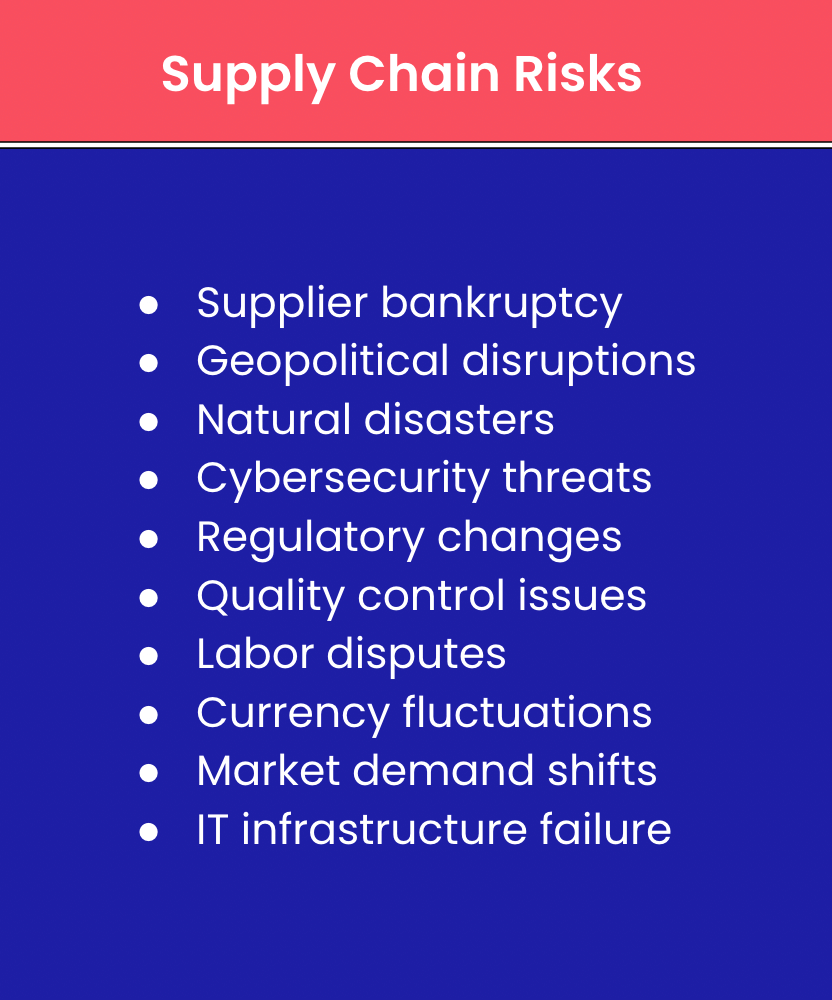

What are the types of risk in supply chain management?

There are several types of risks in supply chain management you could face, including:

- Supplier bankruptcy or financial instability leading to failure in delivering goods or services.

- Disruptions due to geopolitical instability, such as trade restrictions or wars.

- Natural disasters or severe weather conditions affecting production or transportation.

- Cybersecurity threats leading to data breaches or disruptions in digital operations.

- Changes in regulations that can impact the production, import, or export of goods.

- Poor quality control resulting in defective products that need to be recalled.

- Labor disputes or strikes causing delays in production or shipping.

- Fluctuations in currency exchange rates impacting costs.

- Significant changes in market demand leading to overstock or shortage.

- Failure of IT infrastructure disrupting digital processes and communication.

None of these situations are ideal. But sometimes, no matter how well you prepare, you'll suddenly be up against one (or more) of these supply chain risks. Thankfully, you won’t have to struggle for long as we’ve comprised some useful supply chain risk mitigation strategies.

5 supply chain risk mitigation strategies

Gartner reports that 89% of companies experienced a supplier risk event in the past five years.

So, how can you help mitigate these risks?

Here are five supply chain risk mitigation strategies to consider:

Strategy 1: Risk identification and assessment

According to Symantec, supply chain attacks increased by 100% year-over-year in 2021, which emphasizes the importance of identifying and analyzing risks as early in the process as possible. This step focuses on spotting any dangers that could throw your supply chain off track and then sizing up how serious and likely they are.

Don’t worry, you won’t have to rely on a crystal ball to help you spot risks in your supply chain. However, there are a few things you can do to help identify potential risks. These methods could involve using tech platforms for data crunching, carrying out supplier checks, or even just having honest chats with your suppliers.

It's about digging deep to see what could go wrong. From a supplier going bust to political upheavals, or even natural disasters – these are all potential risks that could interfere with your supply chain.

Once you’ve identified the risks, it’s time to assess them. After all, it’s not enough to just spot the risks, you need to understand them.

Ask relevant questions to help assess risks, such as:

- How much damage could they do to your business?

- What's their chance of happening?

…and so on.

Tools like risk charts and predictive analytics can help, giving you insights into which risks should be addressed first based on how impactful and likely they are.

But where does the CFO come in?

Your financial know-how and forward-thinking approach are crucial in understanding the money-related impacts of these risks. It’s up to you to make sure resources are spent wisely to handle and reduce the risks you've identified.

In a nutshell, identifying and analyzing risks is like drawing up a good game plan. It’s the groundwork that paves the way for all the risk reduction work that follows. Developing a business continuity plan will also help to prepare for risks related to supply chains.

Strategy 2: Supplier diversification

Seasoned CFOs know that diversifying suppliers is one of the most beneficial supply chain risk mitigation strategies. Think about it logically – the more suppliers you have spread out in different locations, the wider your safety net. If you're dependent on one supplier, you're playing with fire.🔥

What's good about this approach?

Having different suppliers makes your supply chain tougher and more adaptable. If one supplier drops the ball or an entire region hits trouble, you've got backup options.

Plus, a wide supplier base means better access to extra resources, tech, and skills. All these things can help drive innovation and keep you ahead of the game.

How can you diversify your supplier base?

It starts with widening your search for suppliers and looking at a mix of local, national, and global partners. Keep track of how well suppliers are doing and have a fresh list of backup suppliers at the ready.

As a CFO, you're a key player in making supplier diversification work. You can help decide where to invest in building relationships with a range of suppliers. Your financial insights can also balance the cost of diversification against how much risk it cuts down. This involves looking at pricing, reliability, and quality to ensure diversifying doesn't hurt the bank or how well things run.

Strategy 3: Implementing robust supply chain technologies

One of the most important supply chain risk mitigation strategies is leveraging the right technology. A simple Google search turns up a list of tech solutions claiming to help solidify your supply chain. These range from basic tracking tools to advanced platforms that can streamline the entire process.

But how can technology reduce risks related to the supply chain?

It’s all about 'visibility'.

Having a clear view across your supply chain puts you in a better position to handle risks head-on. You can spot and deal with disruptions as and when they happen, reducing their overall impact. Technology can also give you a heads-up about risks before they happen.

Like most things in life (and business), bringing in new technologies comes with a price tag. You’ve got to consider the cost of buying, setting up the technology, and the cost of training staff, etc.

Once you’ve chosen the right tool, you’ll also have to manage its financial setup, making sure the transition is smooth and keeping an eye on the return on investment.

If you use it right, technology can be a game-changer in managing your supply chain risks. It can not only help you handle risks better but also make operations more efficient.

Strategy 4: Establishing strong contracts and compliance procedures

There’s nothing like official contracts and compliance procedures to brighten a CFO’s day. Whilst both of these things may not be as shiny as high-tech solutions, they're still key parts of a good risk management strategy.

Well-made contracts act as another safety net by setting out responsibilities, expectations, and steps to take if disruptions happen. They can be vital in avoiding arguments, making sure you get paid, or quickly switching to backup suppliers if needed.

On the other hand, compliance procedures make sure everyone in your supply chain is playing fair. They can help with sticking to regulations, ethical sourcing, quality control, and more. Never underestimate the power of a strong compliance program. It can shield you from reputational risks, and legal fines, and help keep your supply chain on the straight and narrow.

When it comes to compliance, your job is to understand the financial fallout of not sticking to the rules and to make sure resources are used effectively for compliance activities. You might also be involved in deciding metrics to measure how successful the compliance program is.

Basically, having solid contracts and compliance procedures makes a rulebook for your supply chain and a game plan for when things go wrong. As a CFO, your know-how makes sure this rulebook is financially sound and safeguards your company's interests.

Strategy 5: Building a resilient supply chain

Resilience is your supply chain's knack for bouncing back from problems, keeping the business going even when the unexpected happens. In today's unpredictable world, resilience isn't just a nice-to-have - it's a must-have.

So, how can you make your supply chain more resilient?

There are various strategies to consider, like the risk assessment and supplier diversification we've discussed, as well as investing in flexible production capabilities. It could also involve nurturing strong relationships with suppliers for better teamwork and communication when trouble strikes.

A resilient supply chain can bring several financial perks:

- Minimized disruptions

- Financial stability

- Enhanced reputation

- Competitive advantage

- Customer satisfaction

- Innovation and increased collaboration

With your financial expertise, you're pivotal to boosting supply chain resilience. You're key in matching risk management strategies with financial goals, making sure the right investments are made to build resilience.

Creating a resilient supply chain might need some initial investment and effort, but in the long run, it can pay off in terms of less risk and sustainable growth.

Other global supply chain risk management strategies

There are more supply chain risk management strategies to consider, so we’ve included some extras below:

Building strong relationships with suppliers

Nurturing solid relationships with suppliers can serve as a strong pillar in your risk mitigation plan. Close partnerships increase reliability and transparency since suppliers may be more willing to share potential risk information early with people they trust.

Working collaboratively with suppliers is a key focus for 53% of senior decision-makers, which proves just how vital collaboration is to increase resilience. In times of shortage or disruptions, you may experience preferential treatment or faster recovery times thanks to the strong relationship you’ve built with the supplier in question. Think of these relationships as strategic investments for maintaining long-term supply chain stability from a financial standpoint.

Inventory management

Managing your inventory effectively is another vital risk mitigation strategy in supply chain management. This involves maintaining a balanced inventory – not too high to escalate holding costs, and not too low to risk stockouts.

Techniques like just-in-time inventory systems can be useful in managing inventory risks. As a CFO, you can play a key role in determining optimal inventory levels and assessing the financial implications of inventory decisions.

Risk transfer

Transferring risk, through mechanisms such as insurance or contractual agreements, can be a savvy move. It allows you to shift some of the work that goes into mitigating risk to other parties, creating an extra layer of protection for your company. Understanding the various risk transfer options and their cost-effectiveness is a crucial part of any risk management toolkit.

Scenario planning

This strategy involves creating a set of forecasts that depict different future scenarios. This practice can help you understand potential risks better and plan responses proactively. As the leader of the finance team, your analytical and strategic planning skills can contribute immensely to developing and interpreting these scenarios.

Continuous monitoring and improvement

Remember, risk mitigation isn't a one-and-done task. It requires ongoing monitoring of the supply chain environment and regular updating of risk mitigation strategies based on new information. Embedding a culture of continuous improvement within the organization is key, emphasizing that managing risk is a journey, not a single destination.

FAQs: Global supply chain risk management strategies

How can we improve supply chain visibility?

Improving supply chain visibility involves integrating technology like IoT devices, AI, and blockchain into your operations. This allows for real-time tracking and monitoring, which can aid in quick decision-making and risk mitigation.

How can we quantify the financial impact of supply chain risks?

Quantifying the financial impact of supply chain risks involves a combination of cost accounting, scenario modeling, and risk probability assessment. A detailed risk assessment plan should be in place to understand potential financial losses from different risk scenarios.

How can we leverage technology for supply chain risk management?

Technology plays a pivotal role in supply chain risk management. Tools like AI and predictive analytics can help in anticipating potential risks and disruptions. Blockchain can improve transparency and traceability, and IoT devices can offer real-time tracking and monitoring.

What should be included in a robust contingency plan for supply chain risks?

A robust contingency plan should detail alternative suppliers, backup storage and distribution facilities, emergency response procedures for natural disasters, and a crisis communication plan. Regular testing and updating of the plan is also crucial.

Follow us on LinkedIn

Follow us on LinkedIn